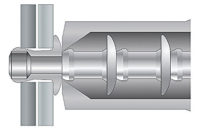

SOLIHULL, UK—The humble rivet. That’s what Demos Hoursoglou, Jaguar Land Rover’s body-in-white manufacturing manager here, puts near the top of his list of worries about assembling the aluminum body of the Range Rover. The 2014 Range Rover body uses 17 types of rivets, 3,722 per vehicle. If one jams in a gun or is inserted incorrectly, production stops. MORE

Rivets Are Essential to Range Rover Assembly