About 300 miles northwest of Mexico City sits the town of Aguascalientes. Although its name means hot waters, the place is much more well-known for its gentle climate, brave bullfighters and being a stopover point between the mines of Zacatecas and Mexico City.

Since 1991, Aguascalientes has also served as the headquarters of Calsonic Kansei Mexicana S.A. de C.V. (CKMSC). A subsidiary of Tokyo -based Calsonic Kansei Corp., CKMSC manufactures fully customizable instrument clusters and HVAC controls for the automotive industry. Its main customer for many years has been Nissan Mexico, which expects to produce about 800,000 vehicles in 2016.

When orders at the Aguascalientes plant increased a few years ago, managers there realized they needed to increase PCB production by shortening solder process time. To achieve this, they replaced the plant’s current soldering machines with two ULTIMA STR2 selective solder systems from Manncorp. After installing the machines, Manncorp technicians spent two days training CKMSC workers on how to program, run and maintain them.

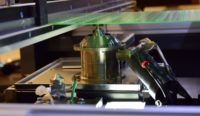

The STR2 system is designed to provide fast, consistent, and high-quality soldering of through-hole components to PCBs. One of its unique features is a high-precision, programmable PCB holder that moves boards in the X, Y and Z axes over a stationary solder pot and wave nozzle with integrated nitrogen preheater. This holder allows for a stable wave as small as 2.5 millimeters in diameter.

The STR2 handles PCBs that weigh up to 2 kilograms (including components), are 0.8 to 2 millimeters thick and measure from 50 millimeters square up to 330 by 250 millimeters. Automatic solder feed mechanisms eliminate the need for the operator to monitor and maintain the solder level in the pot.

Aguascalientes plant managers report that the machines have reduced process time by 30 to 50 percent over the past three years. Equally important, they produce hundreds of zero-defect PCBs daily.

These benefits have not gone unnoticed by plant managers at Nissan plants in Taiwan and Japan. Both facilities now use several ULTIMA solder machines.

Manncorp has supplied PCB assembly equipment for surface mount technology and through-hole electronic manufacturing since the late 1960s. The company serves Mexico from its office in Juarez. Technicians there recently installed two pick-and-place machines, a stencil printer and a reflow oven in the 3D rapid prototyping lab at the Instituto Tecnologico Superior de Zapopan in Guadalajara.

For more information on PCB assembly equipment, call 215-830-1200 or visit www.manncorp.com