In case of a hard coating, such as chrome or paint, the stud should be masked. Photo: Herrmann Ultrasonics

Ultrasonic welding is a commonly used assembly method in the appliance industry. It efficiently addresses the demands for hermetic, high strength welds with superior cosmetic appearance. The growing acceptance of ultrasonic welding is due, in part, to fast weld times (milliseconds) and no post weld curing or cooling.

This technology is used for several applications within the appliance industry, including parts in the control panel such as status display windows, control panel buttons, chrome accent rings, and electrical and electronic components throughout the machine. Door assemblies and sound dampening insulation also are feasible applications for ultrasonic welding.

Twin sonotrodes allow for a significant increase in the weld area. One generator drives two converters and they expand and contract in sequence like a single sonotrode. Photo: Herrmann Ultrasonics

The Basics

Ultrasonic welding of plastics is an intricate task. Each application is unique and places different requirements on the complex interplay of factors. Acoustic waves, or ultrasound, are converted into mechanical vibrations to generate molecular heat. Welded parts are immediately available and do not require cool down or curing time.The weld process is controlled by sophisticated control software and must be adapted to the geometry and condition of the welded parts, which are made from amorphous or semi-crystalline polymers. Each welding tool, the sonotrode, is custom to each application, as it is adapted to the application at hand.

Ultrasonic welding uses 75% less energy than other thermal joining processes, because the welding tools remain cold and has a low energy requirement. The ultrasonic vibrations are specifically applied to the joint area for only milliseconds during welding. New digital ultrasonic generators, with a power output of up to 8,000 Watts, work with an extremely high degree of efficiency of over 80% when powered.

The most commonly used frequencies are 20 kHz for larger parts and 35 kHz for smaller parts. For parts with continuous weld beads that exceed the scope of a single sonotrode, multiple rigid ultrasonic stacks can be mounted in close proximity to each other for an uninterrupted seam.

With the correct energy director design, a continuous weld line can be created for large parts. Newer technologies such as twin sonotrodes, allow for a significant increase in the weld area. One generator is driving two converters and they expand and contract in sequence a single sonotrode with a length up to 16 inches.

When post diameter is greater than 2/3 of the wall thickness, a hollow post design should be considered to avoid sink marks. Photo: Herrmann Ultrasonics

Joining

The most commonly used joining geometries for appliances are direct welding of two compatible plastic parts using an energy director or mechanical fastening of dissimilar components using staking of a solid or hollow post.When welding two injection molded parts together, they should be molded of compatible thermoplastic materials, and one of the parts should be designed with an energy director. For amorphous resins, the angle of the energy director should be between 60 to 90 degrees with a height of 0.3 to 0.4 mm for smaller parts and 0.5 to 0.7 mm for larger parts.

Semi-crystalline resins require an angle of 90 degrees with a height of 0.5 to 0.7 mm for smaller parts and 0.7 to 1.0 mm for larger parts. During the vibration, the energy director will start to melt and create a molecular bond between the two parts. Strength between the parts typically exhibits 80% of the original material strength. Therefore, the cross section of the weld area should be 1.5 times nominal wall thickness, to avoid failure of the parts at the weld interface.

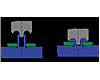

Ultrasonic staking allows quick and clean assembling by melting and reforming a thermoplastic stud. It mechanically locks dissimilar material in place. Strong, gap-free joints overcome the elasticity behavior of the plastic in order to eliminate the “memory” of the plastic. Concentrating the ultrasonic energy to small areas, eliminates thermal overstressing of the material.

Furthermore, the heat generated during the staking process is dissipated by the sonotrode. Low weld force, high amplitude and a specifically designed sonotrode is generally used.

When post diameter is greater than 2/3 of the wall thickness, a hollow post design should be considered to avoid sink marks. Simple staking can be accomplished with sonotrodes made of titanium.

In case of a hard coating, such as chrome or paint, the stud should be masked. If a glass-filled material is chosen, a coated titanium or hardened steel sonotrode should be utilized. Air cooling of the sonotrode might be required in situations of longer weld times.

The use of hydraulic dampening devices has proved excellent for these applications. This ensures a constant weld travel permitting the plastified material to form to the sonotrode face detail. As a result, cold forming is avoided. Radii or recesses help prevent cracks on the base of the staking post. The ratio between the post diameter and its length should not exceed 1:2.

In addition to the ultrasonic joining technologies discussed above, other technologies also can be found in the appliance industry, including inserting, spot welding and slitting.

An increasingly popular option for manual load machines is the use of high frequency switching. Photo: Herrmann Ultrasonics

Manual Workstation

Traditionally, table top machines have been commonly used for parts that could be loaded manually. New developments have helped to increase the throughput of these types of machines.Newer features include fully automated start functions, freely programmable Z axis to start the weld closer to the part, and velocity-controlled Z drive with sophisticated soft impact. Multiple built in I/O in the ultrasonic welding machine allow for easy integration of additional features such as barcode scanners, laser markers, shuttle tables, automatic product selection from the user interface, data acquisition, leak testing and quality control.

Table top machines were commonly used for parts that could be loaded manually. New developments have helped to increase the throughput of these types of machines. Photo: Herrmann Ultrasonics

Semi-Automation

Due to product variants and ever-changing volume size, semi-automated work cells are becoming commonplace within the appliance industry. Handling of delicate or sophisticated parts and efficient production schedules, require increased productivity by allowing people to perform tasks, which cannot be performed by a machine.An increasingly popular option for manual load machines, is the use of high frequency switching. The work station can, as seen in other industries, weld several weld points within a single cycle. The most common practice includes actuation of all the ultrasonic stacks and then sequential switching of the high frequency signal from one ultrasonic generator to multiple stacks.

For example, an application with 30 stacks (or weld points) requires significantly fewer generators. The tradeoff of a modest increase in cycle time is offset by a significant cost savings by reducing the number of generators required. Switching 10 generators three times would increase the overall cycle time by only 4 seconds.

Shuttle tables allow for a safe and ergonomic loading of large parts into an ultrasonic welding machine with multiple weld points. For a fast change over, a complete tool set can be stored inside the machine and, with a quick tool change, the complete machine can run with a new product in less than 5 minutes.

Lastly, rotary tables are a convenient way to enhance manual loading of semi-automated assembly machines. The main advantage here, is that progressive assemblies can be built on a single machine with multiple stations. The fast welding time allows for a high throughput with only a single welder installed on a rotary table. Cycle times, depend on size, but 50 or more per minute are common in the industry. Rotary tables can easily add additional process station and/or automated quality controls.