Automakers are scrambling to build a new generation of vehicles that are intelligent, connected and electrified. That’s forcing engineers to rethink how traditional assembly lines and production processes function.

One company that’s at the forefront of the trend is Nissan Motor Co. The automaker recently announced that it plans to invest $300 million to modernize its factories with advanced equipment and technology.

“These innovations will help deliver a new generation of automobiles that embody the Nissan Intelligent Mobility vision, while also making production operations more flexible, efficient and sustainable,” says Hideyuki Sakamoto, executive vice president for manufacturing and supply chain management.

Following a pilot program at the company’s flagship Tochigi Plant in Japan, the technologies will be rolled out across Nissan global factories.

“This investment represents a necessary rethinking of conventional car making,” claims Sakamoto. “[We will] tackle the structural and technical challenges of producing vehicles that will lead the industry in a new era of electrification and intelligence.

“We’re facing an unprecedented evolution in the capabilities of our vehicles,” adds Sakamoto. “Our job is to make this evolution a reality by rethinking how we build cars. This will also mean shifting the efforts of our expert technicians from techniques they’ve already mastered to new, unexplored areas.”

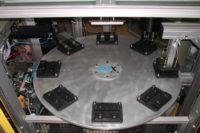

Nissan engineers are implementing a new “universal power train mounting system” that uses an automated pallet to mount an entire power train at once. It measures a car’s dimensions in real time during mounting, and the pallet makes micro-adjustments accordingly.

“This ensures that power trains are installed to within a small fraction of a millimeter accuracy,” says Sakamoto. “It is particularly adaptable and can automatically mount up to 27 internal combustion engine, hybrid or electric power train configurations. No other systems can automatically handle such a broad range of potential configurations.”

The new automated equipment enables operators to assemble a variety of vehicles, each equipped with different types of batteries, power trains and suspensions, on the same line.

“Although we already utilize robots in our plants, we will [now] use them to perform certain specialist skills and processes that could only be performed by trained takumi craftspeople [in the past],” adds Sakamoto. “This was realized through an intensive collaborative process, where craftspeople and engineers digitized parts of these delicate processes and trained robots to perform them around the clock.

“Robots will also be deployed to perform strenuous tasks efficiently, freeing workers to [focus on more value-added] jobs elsewhere on the line,” explains Sakamoto. “This improves ergonomics, making [assembly lines safer] places to work. We expect to be able to reduce the amount of effort and number of steps necessary when we are preparing to produce new models.”

In addition, Nissan plans to use artificial intelligence, data analytics and other Industry 4.0 tools for advanced plant maintenance and quality assurance applications. “This will enable predictive maintenance and remote maintenance for a 40 percent reduction in recovery time,” claims Sakamoto.