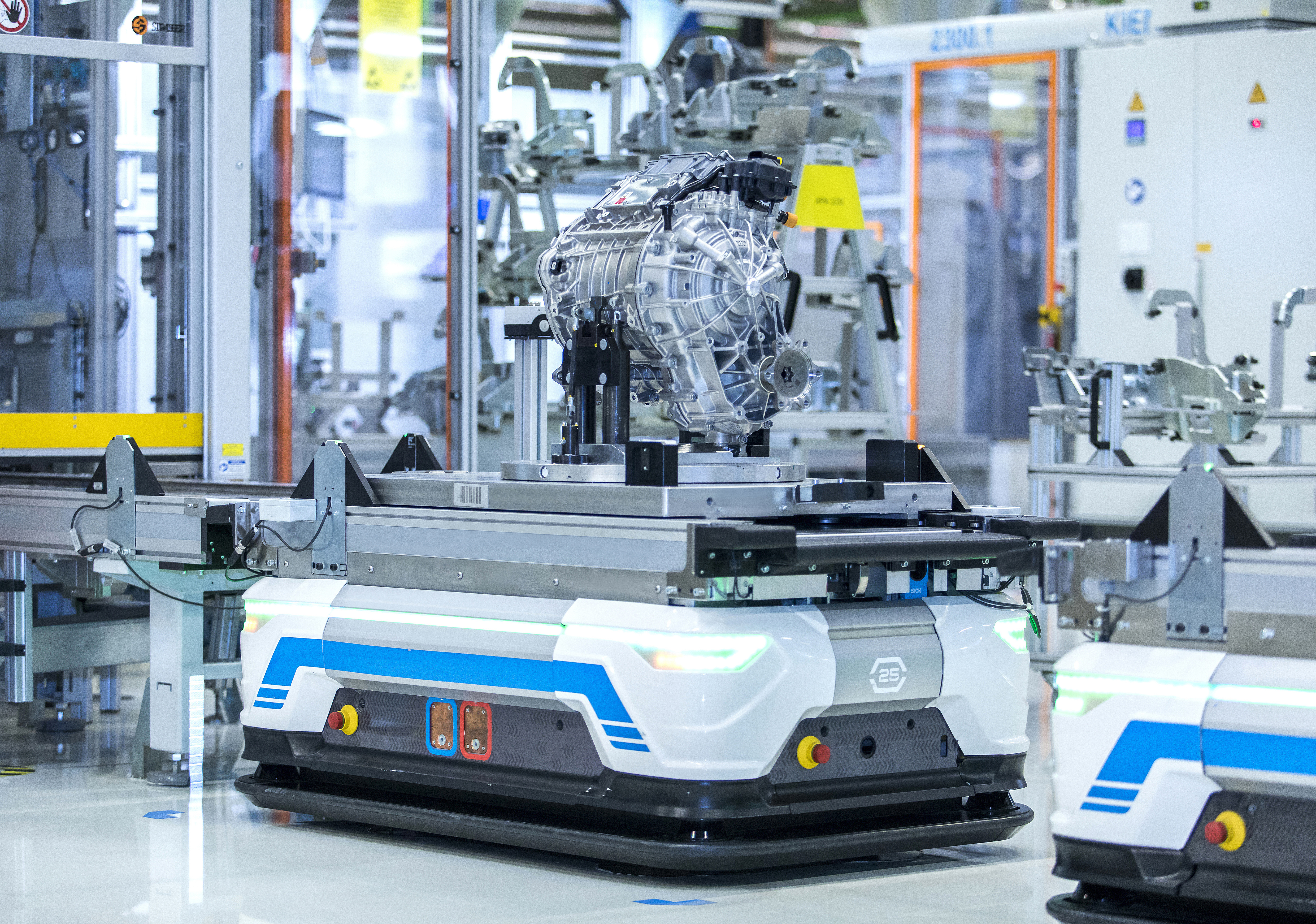

GYOR, Hungary—Engineers at Audi AG’s factory here are preparing new assembly lines that will mass-produce next-generation electric traction motors. When production ramps up, the state-of-the-art facility will supply electric drives for Audi and Porsche Premium Platform Electric (PPE) vehicles.

“In accordance with the Audi Group's electrification strategy, we are actively shaping the new era of electrification as the world's largest drive plant, in addition to producing a large number of efficient combustion engines,” says Alfons Dintner, chairman of the board of management at Audi Hungaria.

“An area of 15,000-square-meters is being expanded in an existing [assembly] hall for the production of the new drives,” explains Dintner. “The future production of the PPE drives will consist of stator and gear component manufacturing, as well as axle assembly. Most of the production equipment has already been installed and preparations for future pre-series production are in progress.

"At Audi Hungaria, we are doing our own development work for electric drives and have been producing e-motors since 2018,” Dintner points out. “Since then, more than 187,163 electric drives have already been assembled.”

To design the new assembly lines, Audi engineers are using virtual reality glasses. “A major advantage here is that the engineers can plan the production process more effectively, and design it innovatively with the use of the new 3D image processing technology,” says Dintner. “This makes the production area more efficient and the [workstations] more ergonomic.”