Home » laser welding

Articles Tagged with ''laser welding''

2021 Assembly Plant of the Year: GKN Drives Transformation With New Culture, Processes and Tools

A two-year-long continuous improvement initiative pays off in Newton, NC.

October 13, 2021

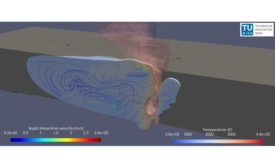

Blue Lasers for Welding Copper

The blue laser produces rapid, high-quality welds for a wide range of part geometries

October 13, 2020

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing