Home » sensors

Articles Tagged with ''sensors''

Sponsored Content

CIP Safety Block Offers IP67 Protection to Connect Safety PLC and Safety Nodes

Memory Key Makes for Quick Replacement Without Commissioning

December 6, 2023

Sponsored Content

Standardizing Sensors and Cables for Improved End-User Experience

December 5, 2023

Sponsored Content

Enhancing Manufacturing Efficiency: OEE Measurement Through Sensors

December 5, 2023

Sponsored Content

The Evolution of Barcode Scanning in Logistics Automation

October 26, 2023

sponsored content

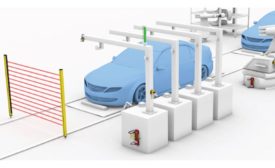

New Balluff Factor 1 inductive sensors ideal for automotive, general factory automation

Barrel and block style sensors deliver identical switching distance for all metals

April 5, 2023

sponsored content

New Generation of Photoelectric Sensors for the Versatile Detection of Objects

Flexible us in Robust Cubic Standard Housing

April 5, 2023

sponsored content

Sensing Ferrous and Non-Ferrous Metals: Enhancing Material Differentiation

March 30, 2023

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing