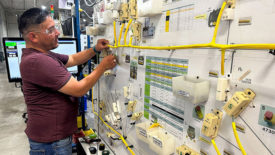

Wire Processing Assembly

Welding

Torsional Ultrasonic Welding Process Joins Metal Parts

Torsional process bonds thick cables, large connectors and thin foils for EV batteries and components.

June 10, 2024

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing