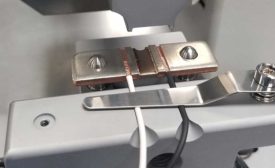

Wire Processing Assembly

Manufacturers have multiple technology options for ultrasonically welding wire to small metal parts

Read More

Culture Drives Efficiency and Quality at Wire Harness Manufacturer

Virginia-based contract manufacturer uses employee input and skill development to build better processes.

July 21, 2020

Cutting and Stripping Coax

The latest technology for stripping coaxial cable gives engineers unprecedented control

April 13, 2020

Options for Tinning Wire

Whether applied manually or by a machine, the tinning process improves the mechanical strength of bare copper wire

April 10, 2020

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing