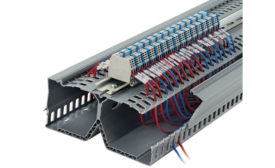

Wire Processing Assembly

3D Printing and Wire Harness Assembly

Harness assemblers are using additive manufacturing to make custom connectors and assembly fixtures.

October 18, 2022

Troubleshooting the Stripping and Crimping Process

Simple error-proofing steps can help avoid big headaches.

July 21, 2022

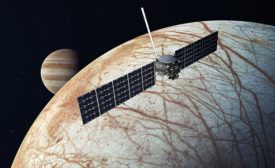

Assembling a Wire Harness for Deep Space

NASA’s Europa Clipper spacecraft poses unique challenges for wire harness design.

June 27, 2022

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing