ARTICLES

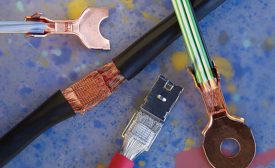

High-velocity collisions create strong welds in dissimilar materials.

Read More

Health and Safety in Post-Pandemic Manufacturing

A comprehensive approach will ensure safety and productivity.

July 15, 2020

How to Speed Up Leak Testing

Leak test manufacturers offer tips to make the process more efficient

May 5, 2020

Common Mistakes When Dispensing and Curing Light- Curing Adhesives

Avoid these common mistakes when dispensing and curing light-curing adhesives

March 5, 2020

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing