Home » Keywords: » two-part adhesives

Items Tagged with 'two-part adhesives'

ARTICLES

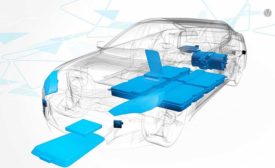

New Technology for Dispensing Two-Part Materials

Electric vehicle applications are driving demand for automated equipment.

January 5, 2021

Troubleshooting the Dispensing Process

Advanced machines help manufacturers flawlessly and consistently dispense a wide range of materials

July 6, 2018

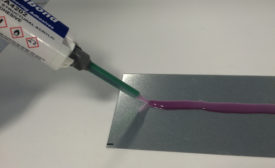

Troubleshooting Adhesive Bonding Issues

When a bonded joint fails, the problem is rarely with the adhesive.

September 8, 2016

What’s New With Meter-Mix Equipment

A variety of high-tech equipment is available to dispense two-part adhesives.

July 1, 2013

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing