Whether it’s an automotive application or an electronics application, engineers are increasingly looking for adhesives that offer high performance at high temperatures. To meet this demand, the adhesives industry has developed a range of products that meet structural, sealing and encapsulation requirements even at temperatures in excess of 200 C.

Although heat-resistant adhesives can bond at high temperatures, it is important to remember that they are still not as strong at high temperatures as they are at room temperature. However, when used correctly, these adhesives will remain permanently stable and perform their function due to the close cross-linking of the polymers.

The need for heat-resistant adhesives exists in numerous industries. In the automotive industry, they are used in such applications as engine sensors and exhaust management systems, where they are also exposed to aggressive chemicals. Heat-resistant adhesives are also used to bond components in the engine bay, where temperature requirements are rising due to the introduction of a new cooling system. Because this new system is more powerful, it generates more heat and strongly affects other components in the engine bay.

Heat-resistant adhesives are also seeing use in the manufacture of power tools. Electric motors are becoming more powerful and generating more heat. More compact motor designs also lead to increased levels of accumulated heat. Heat-resistant adhesives are essential to bond magnets or to fix the rotor to the shaft. For tools like angle grinders, adhesives are applied as a casting compound and are used to fix copper wires found in the rotors of the motors, which can become very hot. The adhesives protect the wires against damage by abrasion caused by airborne particles.

Heat-resistant adhesives are also found in power electronics. Machinery such as locomotives and oil-drilling equipment use so much power that electric components can reach temperatures of more than 200 C. Conversely, in the aviation sector, heat-resistant adhesives are seldom required because of ambient temperatures. When they are used, it is only in areas that are close to the engine, like the inlet, the fan blades or the front guide wheels.

What Makes Adhesives Heat-Resistant?

To understand the principle of heat-resistant adhesives, it is helpful to know the meaning of three terms: temperature resistance, glass transition temperature and thermal stability.

Temperature resistance indicates the extent to which adhesive and cohesive properties are retained even after storage at high temperatures.

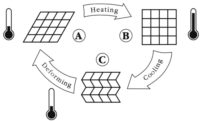

Glass transition temperature is the temperature at which a polymer changes from a crystalline structure to an amorphous structure. In other words, it’s the temperature at which the material changes from glassy or rigid to softer or more elastic. When this occurs, significant changes take place in its mechanical and physical properties.

Thermal stability is a measure of how long an adhesive remains stable at high temperatures without severe degradation related to char, skinning and viscosity change.

A genuine heat-resistant adhesive will be highly rated on all three of these characteristics.

Heat-resistant adhesives are formulated to be a bit more flexible, without making the cross-links less stable. A certain level of flexibility compensates for stress peaks that occur when the bonded joint is exposed to peeling loads. It also helps the adhesive absorb stress and compensate for differences in coefficients of thermal expansion between the materials being bonded.

The Right Adhesive

If adhesives are required for a high-temperature environment, a variety of adhesive chemistries is available.

Polyurethanes are commonplace as a construction adhesive, but they are not suitable for high-temperature environments in the long term. Not only do they absorb moisture, but they also become flexible and soft under the influence of heat.

Light-curing acrylates are deployed both as a sealant and as an adhesive. The most temperature-resistant products of this type are suitable for temperatures of up to 150 C.

Anaerobic curing adhesives, based on methacrylate, are appropriate for temperatures up to 200 C under normal requirements. If, for reasons of efficiency, a popular light-curing component is integrated, the threshold is 180 C.

By contrast, silicones are mechanically stable throughout a wide

temperature spectrum and are suitable for temperatures of up to 300 C. However, their strength is generally so low that they are suitable under such conditions only for sealing or casting purposes.

That’s because they have a relatively low glass transition temperature. Beyond -70 C, silicones are elastic in nature. This property makes them ideal as sealants, because they remain flexible even below the frost line. However, limitations arise because they are slow to cure and swell. Their high flexibility is due to a wide-meshed molecular network. This enables both good mobility of the polymer chains and the incorporation of foreign molecules like water or oil.

In most cases, heat-curing, one-component epoxy adhesives are the best option for temperatures above 200 C. The performance of these adhesives has improved significantly in recent years. Engineers can choose between two product groups, which have significantly different characteristics due to their resin-hardener combinations.

For structural tasks, epoxy resins with amine curing agents are common. They resist impacts, which is an important characteristic for handling dynamic loads. That’s why these adhesives are often used to bond the surface magnets in electric motors.

Epoxies with anhydride hardeners are even more closely cross-linked, making these products harder and less tension-equalizing. They make excellent high-temperature encapsulants and casting compounds. Another strength of these adhesives for potting applications is that they are extremely resistant to aggressive chemicals, such as gasoline, gear oil or acids.

Some anhydride-based epoxies can be used in temperatures up to 250 C. It may seem contradictory to think that these adhesives can be very hard and yet also flexible enough to adhere well at such high temperatures, but an elongation at break in the range of 5 percent is entirely sufficient for high-temperature resistance in casting applications.

The adhesives industry continues to push the boundaries of chemistry. Once temperatures exceed 300 C, organic materials typically begin to struggle. However, new adhesives are being formulated every day to provide high temperature resistance, good bonding strength, solid temperature stability and low curing times.