The first man-made plastic—created in 1862 as a substitute for the ivory used to make billiard balls—was a bioplastic. Over the last 156 years, the plastics industry has continued to innovate with bioplastics, expanding their properties and the feedstocks from which they come. With these innovations, applications for bioplastics have extended far beyond the pool hall and as they become more common—and break into new industries—it’s important for every company making material decisions to keep bioplastics on their radar.

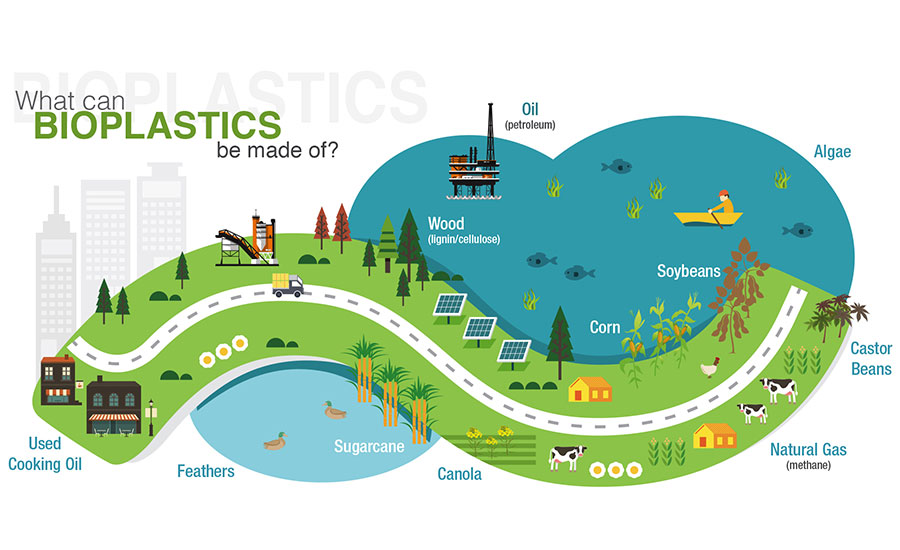

Simply put, bioplastics are defined by the Plastics Industry Association’s (PLASTICS) Bioplastics Division as a type of plastic made from biobased materials like sugar cane or cornstarch, or a type of plastic that is capable of biodegrading through a process such as composting.

While all plastics offer a number of design and manufacturing advantages over other materials, bioplastics can offer a number of additional benefits to companies that use them, helping them cut down on carbon emissions or reduce reliance on fossil fuels by diversifying their feedstocks.

In a Plastics Market Watch report released in May—Watching: Bioplastics—PLASTICS reported that bioplastics are in a growth cycle and currently outpacing the broader economy. By attracting new investments and bringing in new products and manufacturing technologies, bioplastics have become more competitive choices in the plastics marketplace, and this growth will only continue as the number of applications for bioplastics increases.

While bioplastics are most commonly used in packaging applications, new developments have made these materials viable in industries like automotive, electronics, building and construction and even appliances.

In fact, earlier this year, appliance company Electrolux announced it had developed the world’s first bioplastic concept refrigerator where all visible plastic parts are made from polylactic acid (PLA). The PLA used in the refrigerator—a biopolymer that offers an 80% reduction in carbon footprint when compared to traditional materials—was produced by NatureWorks LLC, a world-leading supplier of biopolymers.

Biobased (/bīōbās’d/): means the plastics are made—at least partly—from renewable resources, including corn, sugar cane, soybeans and agricultural byproducts like sawdust.

Biodegradable (/bīōdəˈɡrādəb(ə/): means that the plastics will completely break down through natural processes like industrial/home composting, marine/soil biodegradation, or anaerobic digestion.

Bioplastics can also be introduced in other stages of the manufacturing process, including product design and repair. Many 3D printing technologies—used today to prototype projects or manufacture complex singular parts—rely on bioplastic filaments because they’re versatile, safe for food contact and virtually odor free.

For many companies, introducing bioplastics is an easy decision—beyond their capabilities, the move toward bioplastics is a move toward a demonstrated commitment to sustainability, which is increasingly valued by consumers. According to a survey conducted by PLASTICS, 64% of consumers would prefer to buy a product made with bioplastics.

There are more than 20 unique bioplastic polymers in the marketplace—made from a broad selection of materials ranging from corn to sawdust to algae—with many more being developed and researched. These new developments are opening up new possibilities for bioplastic applications, providing manufacturers with new opportunities to replace some of their materials with a biobased or biodegradable option that matches or exceeds the performance of other traditional plastics. To learn more about emerging opportunities and applications for bioplastics, download the full Plastics Market Watch Report: Watching: Bioplastics, from our website.

The Plastics Industry Association | www.plasticsindustry.org