STERLING HEIGHTS, MI—Ford Motor Co.’s Van Dyke transmission plant here has mass-produced suspension components and transmissions for more than 50 years. However, the automaker recently renamed the facility to reflect its commitment to electric vehicles.

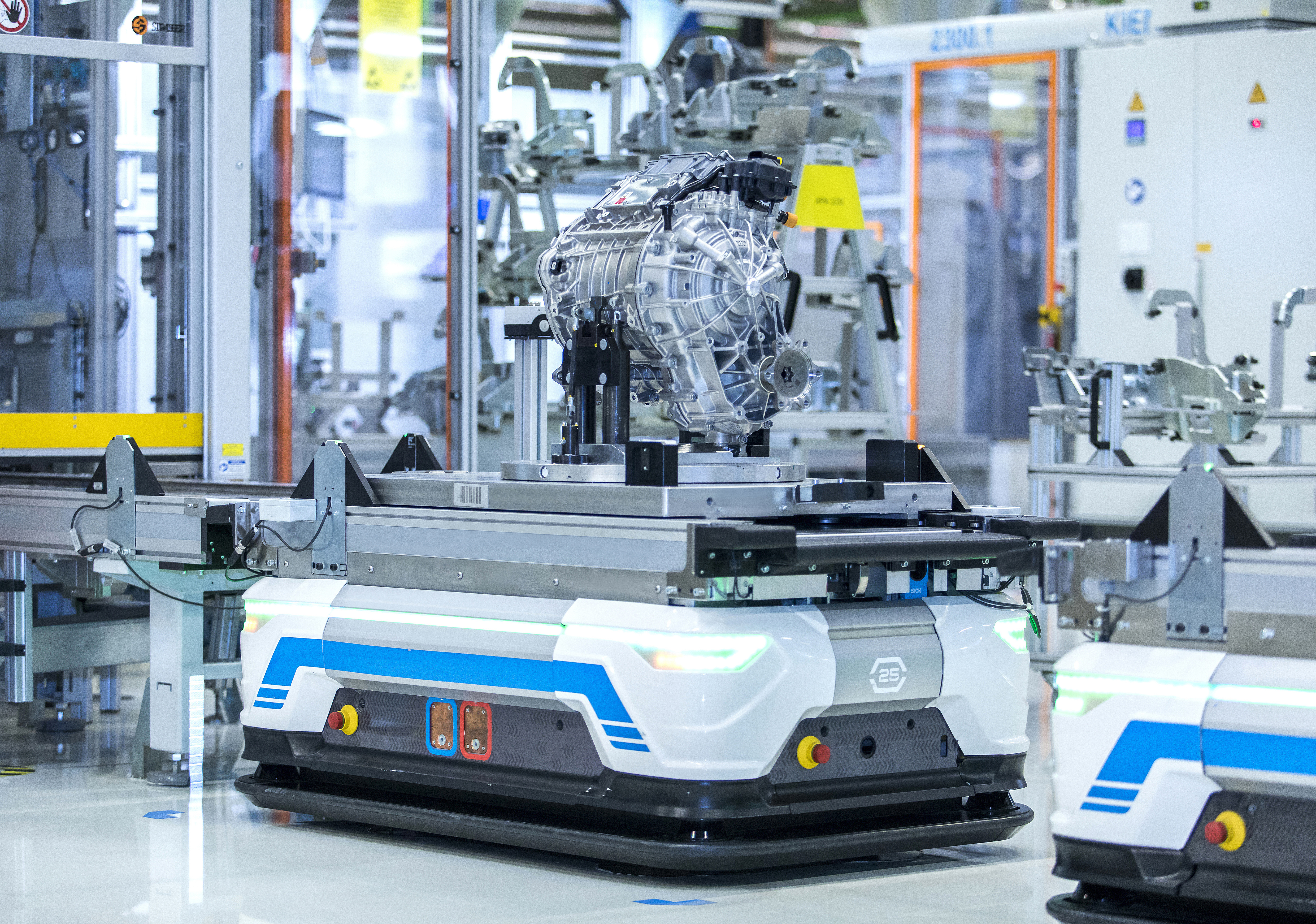

In a nod to the advanced technology it will produce, the 2-million-square-foot assembly plant will now be called the Van Dyke Electric Powertrain Center. As part of a recent $150 million investment, it will produce electric motors and electric transaxles for hybrid and fully electric vehicles, such as the 2022 F-150 Lightning pickup truck, which will be assembled at the company’s flagship Rouge factory in Dearborn, MI.

Currently, the Van Dyke plant produces conventional and hybrid transmissions for vehicles such as the Ford Transit, Edge, Escape, EcoSport, Mondeo, Kuga, S-Max, Galaxy and Lincoln Corsair.

“The advanced technology we are using at the Van Dyke Electric Powertrain Center is taking us to the next level for Ford’s electric future,” says John Savona, vice president of manufacturing and labor affairs at Ford Motor Co. “The electric transformation we are making now is going to allow us to scale quickly as customer interest grows for our new electric vehicles.”

The electric motor is expected to be at full production this summer, with one device coming off the assembly line every 75 seconds. The electric transmission is expected to launch early next year.

“The eMotor features the latest technology in motor design and manufacturing, resulting in a quieter and more efficient motor,” claims Savona. “The eMotor can go into either a hybrid transmission or it can go into the eTrans for a fully electric vehicle.”

When the Van Dyke transmission plant opened in 1968, it produced front suspension parts. The factory built its first transmission in 1993 with a four-speed automatic transaxle transmission for vehicles such as the Ford Taurus and Windstar. It transitioned to a six-speed transmission in 2006 for vehicles such as the Ford Edge and Explorer, and added an eight-speed transmission in 2018 for the Ford Edge.

The facility was the recipient of ASSEMBLY Magazine’s 2018 Assembly Plant of the Year award. It was honored for its flexible manufacturing strategy and its application of state-of-the-art manufacturing technology.