Home » composites assembly

Articles Tagged with ''composites assembly''

Effects of Plasma Treatment on Bonding CFRP

By removing surface contaminants, plasma treatment can improve the bondability of CFRP.

August 2, 2022

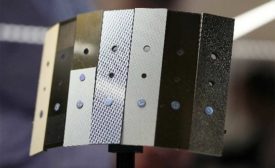

Spot Welding Metal-Plastic Composites

A new resistance spot welding process can join metal-plastic composites

April 7, 2022

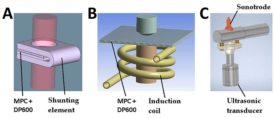

Ultrasonic Welding of Thermoplastic Composites

Strong and lightweight, thermoplastic composites can be difficult to join.

September 7, 2021

New Materials, New Fasteners

As automakers replace steel with lightweight materials, new fasteners will replace conventional screws.

June 11, 2021

New Developments in Self-Pierce Riveting

New technology incorporates the advantages of self-pierce riveting while overcoming its limitations.

January 6, 2021

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing