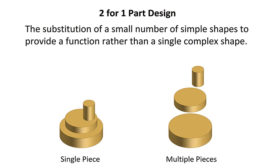

DFMA Assembly

Countering Old-School Views on Design

When designing products, engineers should focus on overall assembly efficiency rather than the cost of individual parts.

June 3, 2016

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing