Test and Inspection Assembly

3D Sensors and Mixed-Model Assembly

Robots and 3D smart sensors are enabling automated mixed-model assembly across a wide range of industries.

November 13, 2017

2017 Assembly Plant of the Year: AGCO Leads the Field With Lean Technology

Wearable devices help build better tractors in Jackson, MN.

October 4, 2017

Four Sources of Inaccuracy in Sensor Measurements

Electromagnetic signal interference and other factors can adversely affect the measurement accuracy of sensors

September 18, 2017

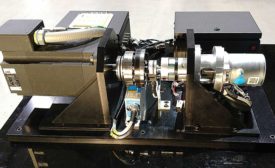

Force and Torque Sensors

Advanced technologies increase the accuracy of force and torque sensors used in product assembly and end-of-line testing.

June 7, 2017

Ingress Leak Testing

Engineers have a couple of options for determining if fluids can penetrate an assembly.

May 5, 2017

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing