What are Glass Bubbles?

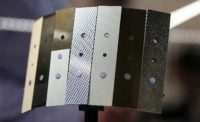

Additives, especially inorganic solid particulates, have greatly contributed to the growth of the polymer industry. They render polymers with improved mechanical, physical, electrical, thermal and dimensional properties, depending on their geometry and chemistry. Glass bubbles are finely dispersed, free-flowing powders consisting of thin-walled (0.5-1.5µm) spherical glass particles with an average diameter of 15-65µm (see Figure 1).

Glass bubbles were developed in the 1960s as an outgrowth from the manufacture of solid glass beads. They are commercially manufactured by melting a unique glass formula that contains a latent blowing agent causing the molten glass particles to expand into a hollow bubble. The resultant glass bubbles are chemically stable, water resistant and compatible with many materials used for indirect food contact applications. The material technology has evolved in recent years to produce bubbles with a high strength to density ratio which enables their use in demanding polymer processing operations.

Density Reduction in Polymer Composites

Glass bubbles can provide new and unique material and design solutions for innovative users. They render polymers with lower density which is directly related to thermal conductivity and insulation properties as shown in Table 1 (below). The three polymer systems shown in Table 1 are common in appliance applications for either housings, walls or, in the case of thermoset polyurethane (PU), already used as a foam material for insulation. Polyurethane foam for appliance insulation is usually made with a chemical blowing agent and can achieve a very low density (0.20 – 0.40 g/cc). Typical polyurethane composite density with glass bubbles is in the 0.76 – 0.95 g/cc range so they are not competitive with urethane for achieving the highest insulation properties. But the unique property of the glass bubble foam is that it is rigid and structural and can be applied to the walls and housings themselves for additional insulation value. This may help appliances that are on the edge of an ENERGY STAR rating to move to that level.

Weight or mass reduction can be helpful in other ways such as helping to reduce shipping costs and ease installation issues. Glass bubbles can provide weight reduction for thermoplastics, thermosets and elastomeric polymer substrates.

The addition of glass bubbles to a polymer will result in physical property changes (density being the obvious one). Typically glass bubble addition will cause the composite to become stiffer than the original unfilled base resin. This can be useful for making stronger yet lighter housings and parts but impact strength is usually inversely related to stiffness. Impact usually becomes the property of focus for material specifiers trying to balance the benefits of mass reduction with other physical properties.

The choice of a specific bubble for a given application is important to maximize density reduction and to minimize cost-in-use. Not all glass bubbles can survive all polymer processing methods. As shown in Figure 2, the relationship of strength to density is important in selecting the lowest density glass bubble that will survive the process. With thermoset materials like polyurethanes and epoxies the predictive step in the process is the type of mixing system used. For high shear thermoset mixers such as Cowles mixers, a 3000 PSI bubble or higher strength material is generally required. For thermoplastics and rubber where there is only an extrusion process involved (e.g. sheet extrusion for thermoforming), then typically at least a 5000 PSI bubble is required. Injection molded thermoplastics require the highest compressive strength bubble – generally 16,000 PSI or greater. Finding the lowest density bubble that survives the process will insure the lowest cost in use since the least amount by weight will be required to achieve the targeted composite density.

| Table 1 | Polymer Type | |||

|---|---|---|---|---|

| HIPS | PU | PP | ||

| Glass Bubble Grade | Density (g/cc) |

K Value Bubble Filled Resin (W.m.°K) |

K Value Bubble Filled Resin (W.m.°K) |

K Value Bubble Filled Resin (W.m.°K) |

| None | -- | 0.15 | 0.19 | 0.21 |

| K1 | 0.125 | 0.094 | 0.112 | 0.121 |

| K20 | 0.2 | 0.106 | 0.125 | 0.134 |

| K25 | 0.25 | 0.115 | 0.133 | 0.143 |

| S32 | 0.32 | 0.126 | 0.145 | 0.154 |

| S35 | 0.35 | 0.13 | 0.15 | 0.159 |

| K37 | 0.37 | 0.133 | 0.153 | 0.163 |

| S38 | 0.38 | 0.135 | 0.155 | 0.164 |

| S38HS | 0.38 | 0.135 | 0.155 | 0.164 |

| K42HS | 0.42 | 0.141 | 0.161 | 0.171 |

| iM16K | 0.46 | 0.147 | 0.167 | 0.177 |

Other Benefits

There are several other benefits of adding glass bubbles into polymers in addition to weight reduction. These can be outlined as improved warpage and dimensional stability, increased productivity due to faster cooling cycles, decreased coefficient of linear thermal expansion (CLTE), decreased acoustical transmission, increased bulk modulus, hardness, scratch resistance, and heat distortion temperature.

In injection molding, shrinkage and warpage constitutes a major problem resulting in decreased productivity. Comparing the geometry of glass bubbles to other fillers in Figure 3, the spheres stand out as being isotropic and create isotropic physical properties in composites. Since they are spherical they do not align in the polymer flow direction like high aspect ratio fillers such as fibers or talc and therefore have a better balance with respect to CLTE, impact, strength and other physical properties.

Glass bubbles decrease the amount of differential shrinkage which results in reduced warpage compared to high aspect ratio fillers are used. An example is shown in Figure 4 for glass fiber filled nylon 6 and talc filled PP. Differential shrinkage is shown as a result of different amounts and types of fillers as well as different post injection hold pressures (pack pressure). Differential shrinkage is higher in the cases where there is high aspect ratio filler present (fiber or talc) without glass bubbles.

Productivity improvements can occur with the addition of glass bubbles. This is due to faster cooling cycles such as in injection molding or thick extrusion profiles. The overall volumetric heat capacity of glass bubble filled polymers is lower than that of their unfilled counterparts resulting in faster cooling from the melt. A study was made at 3M on an injection molded cabin air filter frame where PP containing 20wt.% talc was reformulated by removing the talc and adding the same amount of glass bubble on a volume basis. Figure 5 shows the cycle as a function of time (seconds) for the talc system (PPTV20) vs. the glass bubble containing material (PPGB20). The optimized cycle was reduced 3.4 seconds with PPGB20 compared to a total cycle time of 16.6 seconds with PPTV20. This is a 20% reduction in cycle time or, stated in terms of productivity, a machine that is capacity constrained can make 20% more parts in a given period of time.

Polypropylene

Glass bubbles allow innovative users to do more and make more by adding these unique fillers to common polymeric materials. They render polymers with lower density and reduced thermal conductivity while preventing warpage and excessive shrinkage of molded or extruded plastics helping to reduce scrap and rejects. Glass bubble containing polymer parts can be manufactured more efficiently due to faster cooling times increasing productivity.