Plastics & Metal Welding Assembly

Spot Welding Metal-Plastic Composites

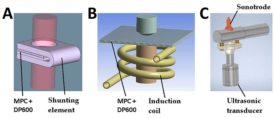

A new resistance spot welding process can join metal-plastic composites

April 7, 2022

Spin Welding for Plastics Assembly

Enhanced data gathering and automation features complement spin welding’s ability to join plastic parts with a round-to-round interface.

February 1, 2022

Harness Shop Masters Difficult Wire Assemblies

For Chief Enterprises LLC, the formula for success is straightforward: Build the uncommon wire harnesses that no other shop wants to.

January 12, 2022

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing