Plastics & Metal Welding Assembly

Optimizing the Spot Welding Process

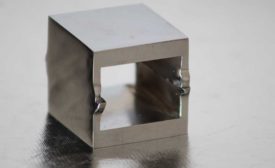

Spot welding can be improved in many ways, starting with selecting the right machine, maintaining heat balance and using advanced controls.

April 13, 2021

How Automation Accelerates Reshoring—Part 2

February 9, 2021

Vibration Welding Adapts to Shifting Demands

Additive manufacturing, electric vehicles and packaging are new applications for vibration welders.

February 8, 2021

Reliable Bonding for Autonomous Driving

Ultrasonic welding is a fast, reliable method for attaching connectors to cables used in self-driving cars

January 12, 2021

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing