Adhesives & Dispensing Assembly

The key to success with pressure-sensitive adhesives is to match the chemistry with the application.

Read More

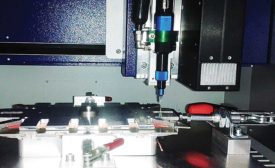

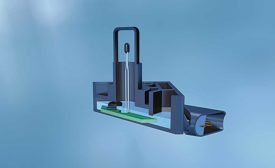

New Technology for Micro-Dispensing

Noncontact jetting offers distinct advantages over needle-based technology for micro-dispensing applications.

October 19, 2017

Using Urethane Adhesives

Available in one- and two-component formulations, urethane adhesives are ideal for bonding metal, plastic and composites.

August 7, 2017

Dispensing Fluids for Portable Electronics

Manufacturers need equipment versatile enough to accurately dispense materials ranging from thin adhesives to thick solder paste.

July 5, 2017

Adhesives Aid Truck and Trailer Assembly

High-strength adhesives and sealants can improve the durability and appearance of trailers and truck bodies, while enhancing throughput.

June 7, 2017

Ammunition Sealants and Bullet Pull Strength

UV-curing external ammunition sealants can make bullet pull strength more consistent and thereby improve performance and accuracy.

June 7, 2017

Heat-Resistant Adhesives

Epoxies top the list of adhesive chemistries that can take the heat.

May 5, 2017

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing