Adhesives & Dispensing Assembly

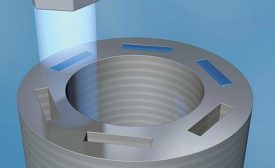

Scheugenpflug’s vacuum potting system ensures quality encapsulation of high-voltage capacitors for medical devices.

Read More

Find the Right Medical Adhesive

Answer these five basic questions to select the ideal adhesive for your medical application.

May 1, 2018

Low-Pressure Molding Controls Stress on Wire Assemblies

Hot-melt molding is the quick and efficient way to encapsulate and protect electrical components.

April 13, 2018

Powder Coating and Adhesives

With the right formulation, engineers can reap the benefits of adhesive bonding and powder coating

April 10, 2018

Alternative UV-Curing Adhesives

A new generation of UV-curing silicones and epoxies are increasingly being used in automotive and electronics applications.

March 6, 2018

Sealing Crimped Contacts Avoids Corrosion

Miele uses a dual-curing adhesive to seal electrical contacts in its washing machine motors.

January 16, 2018

Tear It Down to Make It Better

Teardowns can reveal product improvements related to adhesives, sealants and coatings.

January 10, 2018

Hot-Melt Adhesives for Electronics Assembly

A new generation of hot-melts is being used to assemble smartphones, tablet computers and other electronic devices.

January 5, 2018

Assembly With Pressure-Sensitive Adhesives

The key to success with pressure-sensitive adhesives is to match the chemistry with the application.

November 20, 2017

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing