Home » Keywords: » high-mix assembly

Items Tagged with 'high-mix assembly'

ARTICLES

MJM Industries serves manufacturers worldwide with high-quality wire and cable harnesses, control panels, electromechanical devices and engineering services.

Read More

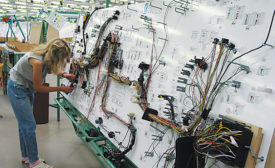

Quality Assurance in Wire Harness Production

Manufacturing execution systems reduce error during manual assembly of automotive wire harnesses

October 13, 2018

2018 Assembly Plant of the Year: Ford Shifts Flexible Assembly Into High Gear

The Van Dyke transmission plant excels at high-volume, high-mix production.

October 2, 2018

2017 Assembly Plant of the Year: AGCO Leads the Field With Lean Technology

Wearable devices help build better tractors in Jackson, MN.

October 4, 2017

What’s New With RFID

RFID technology has become critical for assembling cars, appliances and other high-value, high-mix products.

August 7, 2017

Vision Enables Flexible Assembly

A new, flexible assembly system produces the same volume and part mix as six older machines.

January 5, 2017

Cable Manufacturer Goes From Generally Good to Specifically Great

Guided by a principle from a best-selling book, every Components Express employee focuses on one thing: making the best machine vision cables in the world.

October 4, 2016

Handling High-Mix Harness Assembly

Organization, flexible equipment and standard work are the keys to handling high-mix production.

July 1, 2016

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing