Adhesives & Dispensing Assembly

Options for Semiautomatic Dispensing

Handheld, powered dispensers provide the answer to many assemblers’ needs.

June 26, 2023

Automated Dispensing for EV Motor Assembly

A fully automated line dispenses and cures a filled, two-part epoxy to encapsulate bus bars for ev motors.

June 8, 2023

Adhesives and Dispensing

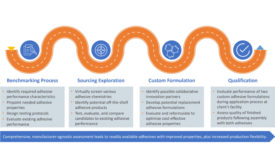

The Sticky Business of Adhesive Sourcing and Replacement

The process of identifying alternative sources for adhesives is more complex than that for other assembly components.

June 1, 2023

Adhesive Tapes Play an Important Role in EV Assembly

PSAs provide durability, functionality, strength and versatility.

May 8, 2023

Coating Improves Grip on Game Controller

A sprayable, UV-cure coating provides a nonsticky, textured feel for video game controllers.

March 8, 2023

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing