Wire Processing Assembly

Toyota has developed a new technology for recycling the copper contained automotive harnesses.

Read More

Robotic Assembly of Automotive Wire Harnesses

New research suggests that six-axis robots can be used to install automotive wiring harnesses.

July 1, 2014

Testing Automotive Wire Harnesses

Today’s testers can quickly perform continuity, hipot and component-specific tests on simple and complex harnesses.

April 1, 2014

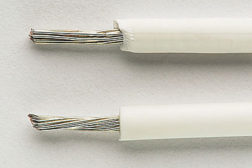

Laser Wire Stripping

Lasers are a clean-cut alternative to mechanical blades.

April 1, 2014

Choosing Wire Terminals and Contacts

Wire terminals are available in a wide variety of designs.

April 1, 2014

Does 3D Printing Work with Wiring?

Additive manufacturing can be used to produce connectors and terminals.

October 1, 2013

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing